How to use the DRYIT semi-continuous tray dryer

Practical Action

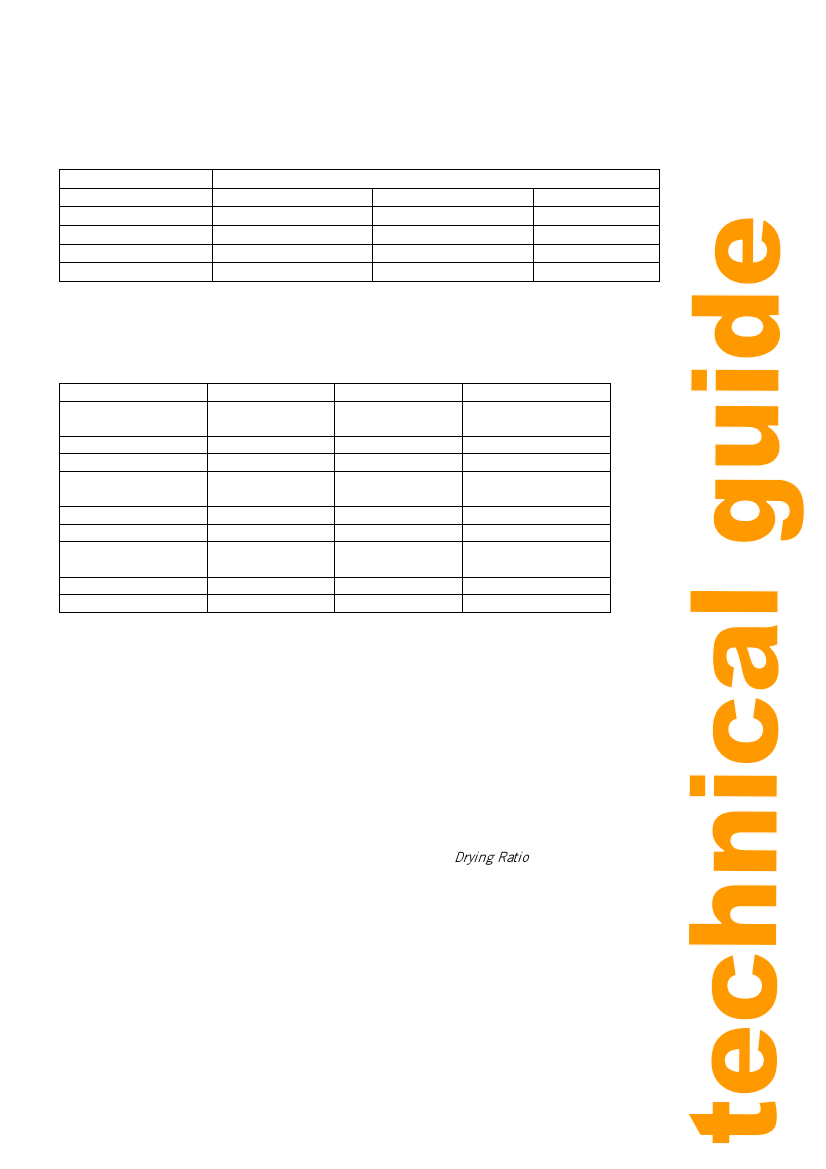

The Selected sound fruit from the above test was then peeled and stoned and the % of usable

flesh weighed.

Supplier A

Supplier B

Supplier C

% of usable flesh

Variety 1

40

42

39

40.3%

Variety 2

46

47

45

46.0%

Variety 3

52

50

53

51.6%

This shows that the usable flesh depends on the variety and not on the supplier.

Knowing the relative prices of the 3 varieties, from the 3 suppliers, will now allow the

processor to decide which is the most economic to use.

Supplier A

(price per 100 kg)

Wt usable flesh (kg)

Cost of usable flesh

Supplier B

(price per 100 kg)

Wt usable flesh (kg)

Cost of usable flesh

Supplier C

(price per 100 kg)

Wt usable flesh (kg)

Cost of usable flesh

Variety 1

$10

36

27 c / kg

$8

37.1

22 c / kg

$10

35.1

28c / kg

Variety 2

$10

42.3

24 c /kg

$10

43.2

23 c /kg

$8

40.9

19.5 c /kg

Variety 3

$15

44.7

34 c/kg

$12

46.4

25 c/kg

$14

41.3

33 c/kg

This example shows that the best choice would be Variety 2 from supplier C which is not

perhaps the obvious conclusion from the original raw data and demonstrates how some simple

trials can affect profits. If supplier B and variety 3 had been selected (as the best in Table 1

above) prepared pulp would cost $250/ton while the final choice only cost $195. Once again

however 'life is not so simple' .It might well be found that one variety after drying had a much

better colour or flavour. This again would affect the final choice with questions having to be

asked as to whether using this variety would win a market, or put the price up to an

uncompetitive level.

Product drying ratio

During the drying process moisture is removed from the food product, so the weight of final

dry product is always less than the original weight put into the dryer. The ratio between the

final dry weight and initial weight put into the dryer is called the Drying Ratio and depends

upon the initial moisture and final moisture contents.

Initial moisture content. Ideally this needs to be checked in a laboratory but books are

available that give typical levels of a wide range of commodities. In general, moisture levels

of fresh produce lie between 75 and 90%.

The final moisture content depends on the product in question. It must be low enough to

make sure that micro-organisms such as moulds cannot grow.

8